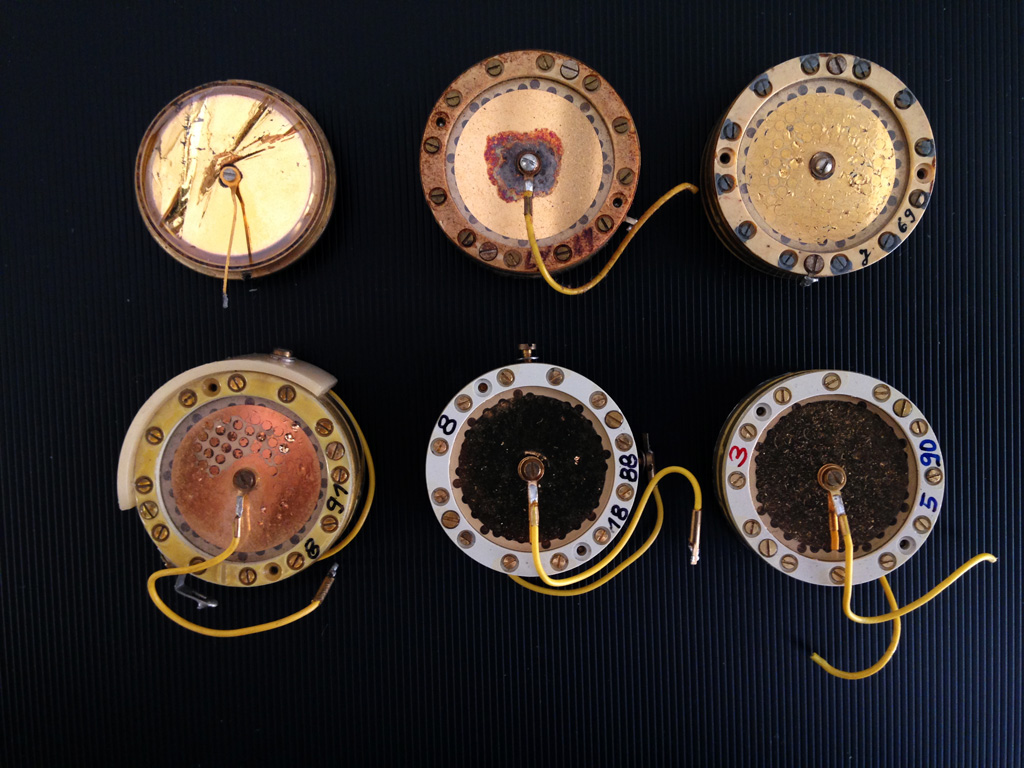

Neumann large diaphragm condenser microphone capsules.

/While sending some condenser capsules to my trusted workshop for restoration, I realized I had in my hands the history of studio microphones:

An original M7 and various editions of the K87 and K67, all genuine Neumann/Gefell specimens, the reference sound of music production from the '50s to today.

Fascinating, inimitable, beautiful even just to look at. These capsules are the result of meticulous and distinctive research by German engineers, and if they have had no rivals for over 60 years, the reason is simple: they sound damn good.

Each capsule characterizes a condenser microphone according to its distinctive tone, and although the design of the amplifier circuit continues to change (tubes, transistors, back to tubes, with and without transformers, etc.), our favorite large-diaphragm capsules survive this constant evolution. It's now more a son of marketing than real technical needs.

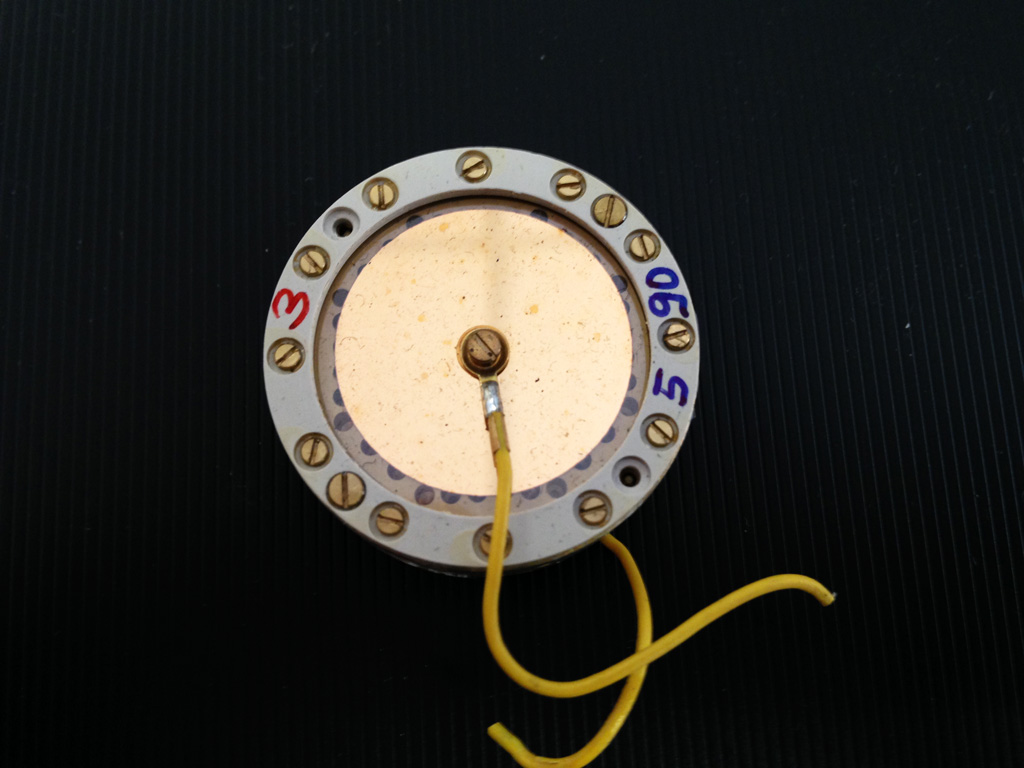

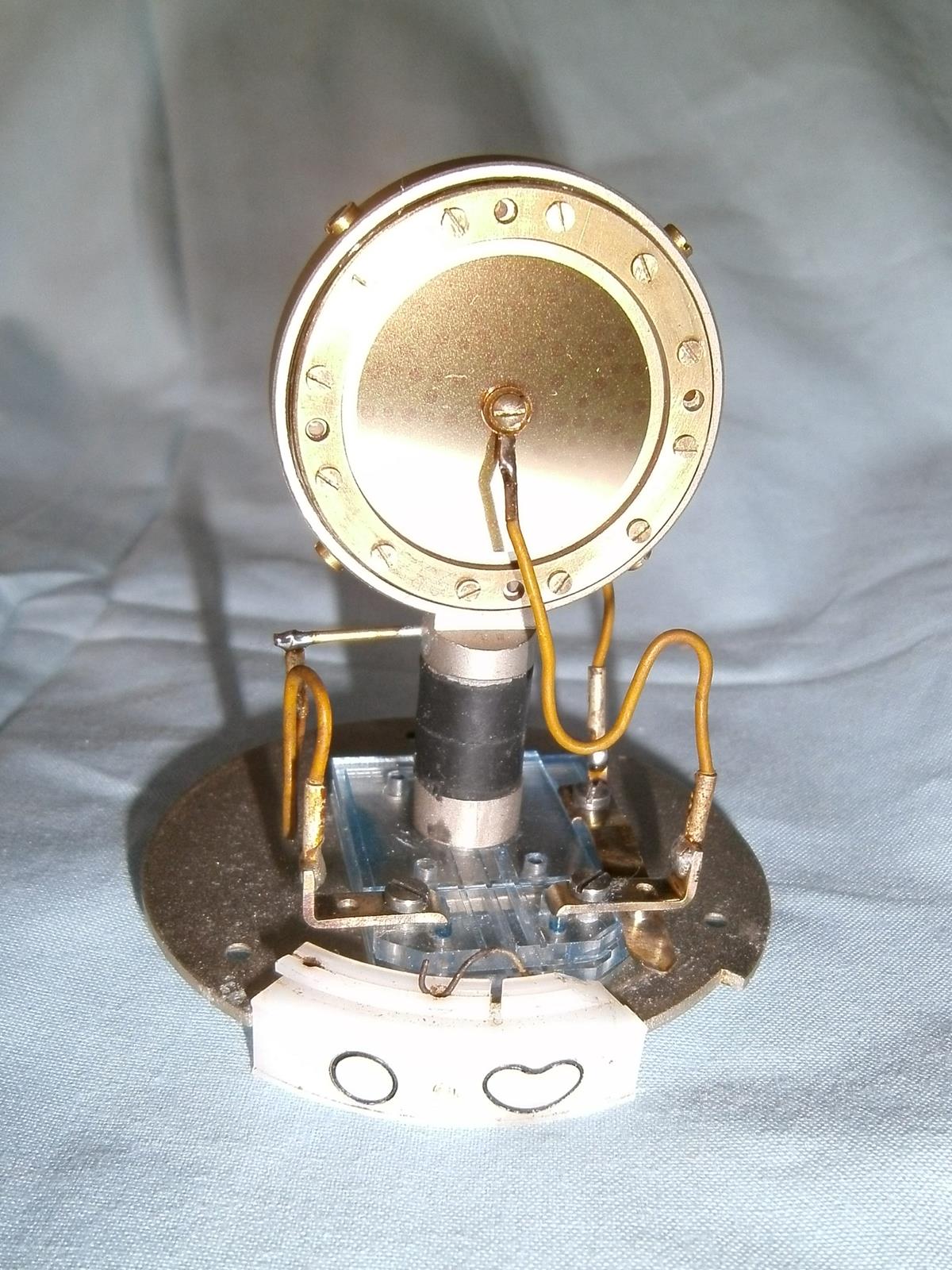

This is an M7 capsule, a large-diaphragm condenser from Neumann/Gefell dating back to around 1957.

The design is the work of engineer Georg Neumann himself, who, perhaps somewhat unwittingly, revolutionized the way we record and listen to music with this project.

The double membrane is made of PVC (Poly-Vinyl-Chloride), a liquid polymer plastic deposited on a glass support to create an extremely thin membrane, approximately 8 - 10 micrometers thick.

Unlike modern Polyethylene membranes (such as Mylar and Hostaphan), which also come in thicknesses of 3 or 6 microns, PVC is much more challenging to work with and is more prone to degradation over time. For this reason, it's very difficult to find an original M7 capsule that has retained its characteristic tone.

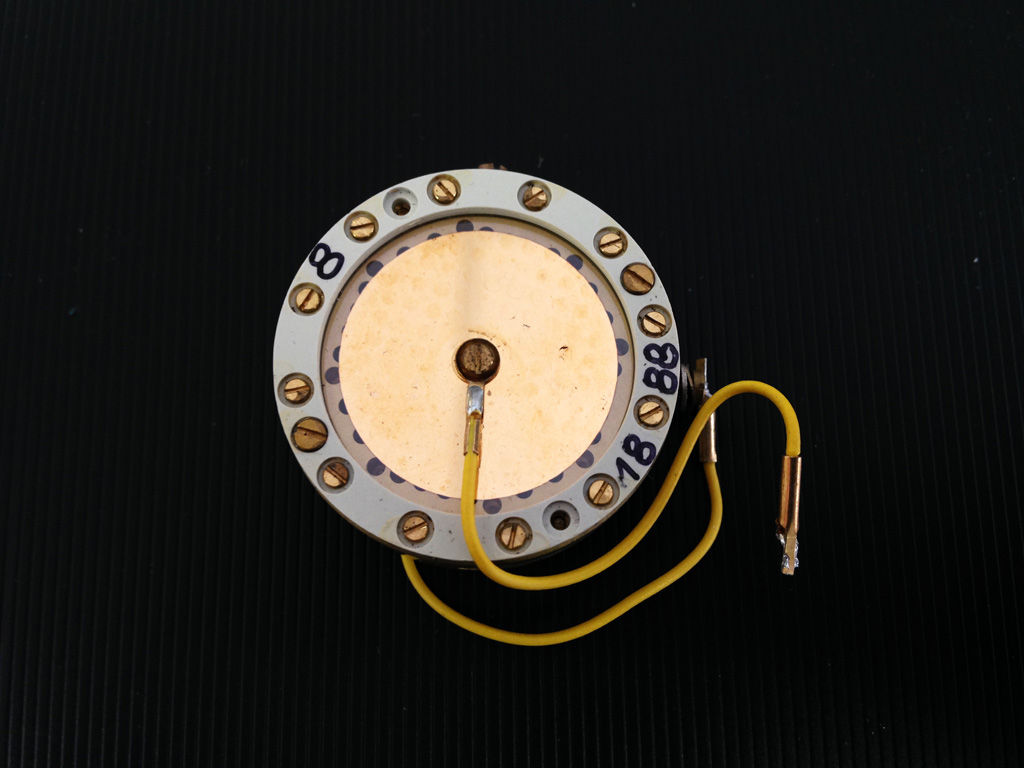

In the 1960’s a new capsule was introduced, called the K67, the beating heart of the new Neumann condenser microphone, the U67.

As Telefunken ceased production of the VF14 tube (Neumann was the sole buyer, and the costs for the factory were no longer sustainable), engineers set to work to launch a new condenser microphone model, the U67, which quickly became the reference microphone in recording studios worldwide.

The transition to Mylar had already occurred between the M7 and the K47, as well as the membrane mounting system (screwed instead of glued). Additionally, unlike the K47, which shares the same drilling pattern with the M7, the new backplate has an innovative design. These features give the microphone a sound very different from its predecessors. The K67/K870 is the same capsule found in modern U87 Ai studio microphones.

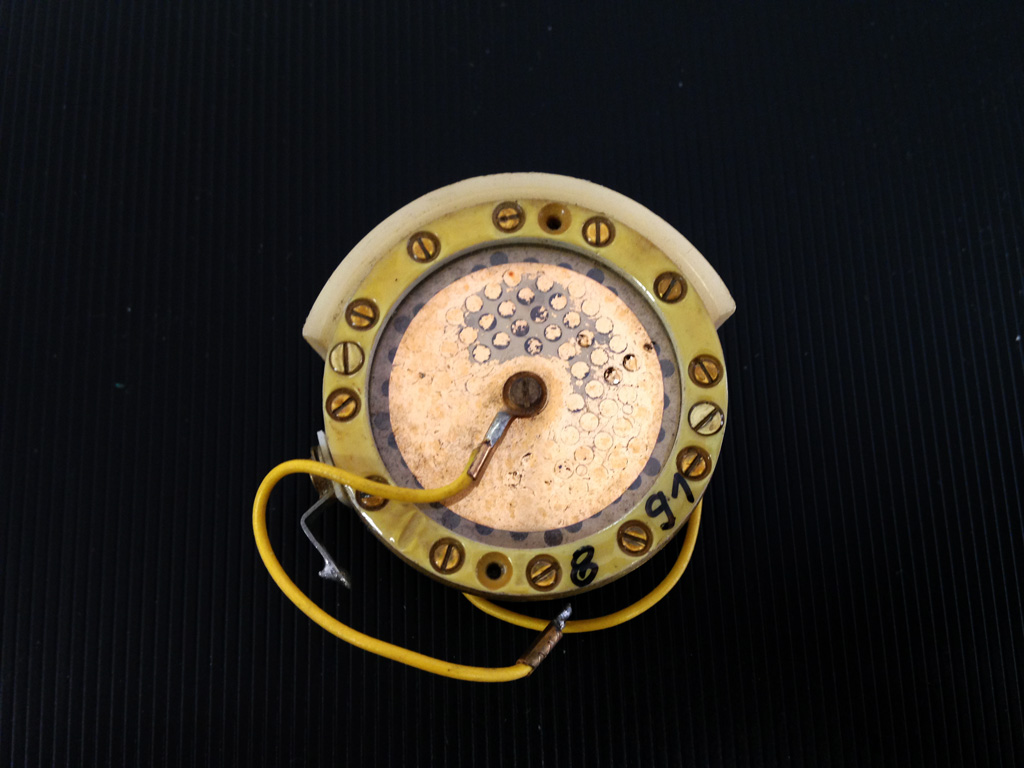

At the end of the 1960s, with the advent of transistor technology, a new studio condenser microphone, the famous U87, was introduced.

For various design improvements, a new capsule called K87 was introduced. It shares the same drilling pattern as the K67, but this time divided into 2 electrically isolated backplates. In fact, it's the only capsule with 4 contacts instead of 3 (2 membranes and two fixed electrodes). In essence, the K87 is exactly a K67 with the two backplates isolated (this means that if the two electrodes of an 87 are electrically contacted, a 67 is obtained, but the reverse is not achievable).

Missing from the lineup are the K47 and K89, mounted respectively on U47/M49 and U89.

The capsule is the beating heart of a microphone, being largely responsible for its tonality and often the component that determines its final cost, at least for the handmade condenser microphones we design and produce at the Braingasm laboratory. For more refined tastes, we choose M7 capsules (Thiersch Red Line in Mylar or original Microtech Gefell PVC) for projects in the style of the U47, or Tim Campbell for projects in the style of Elam or C12.

Some of these K67 and K87 capsules that will be restored are part of an ambitious project in collaboration with a highly talented sound engineer with whom we are designing custom signature models. Stay tuned!